BRIGHT DIP ANODIZING FOR ALUMINUM

Bright Dip Anodizing Services Available:

Our experts offer a comprehensive suite of services related to Bright Dip Anodizing.

Cosmetic Enhancement:

- Bright Dip Anodizing is all about aesthetics. It’s the go-to choice when you want to elevate the visual appeal of your aluminum parts. Whether it’s automotive components, machine parts, architectural trim, or light reflectors, our process ensures a glossy, reflective finish that catches the eye.

Color Variety:

- Bright Dip Anodizing isn’t limited to a single shade. We offer a wide range of colors, allowing you to customize your aluminum parts to match your design preferences. From sleek silver to vibrant hues, the choice is yours.

Longevity & Corrosion Resistance:

- Anodized aluminum has a longer lifespan compared to untreated aluminum. By creating that protective oxide layer, we ensure your components withstand the test of time, even in challenging environments.

Complex Part Shapes:

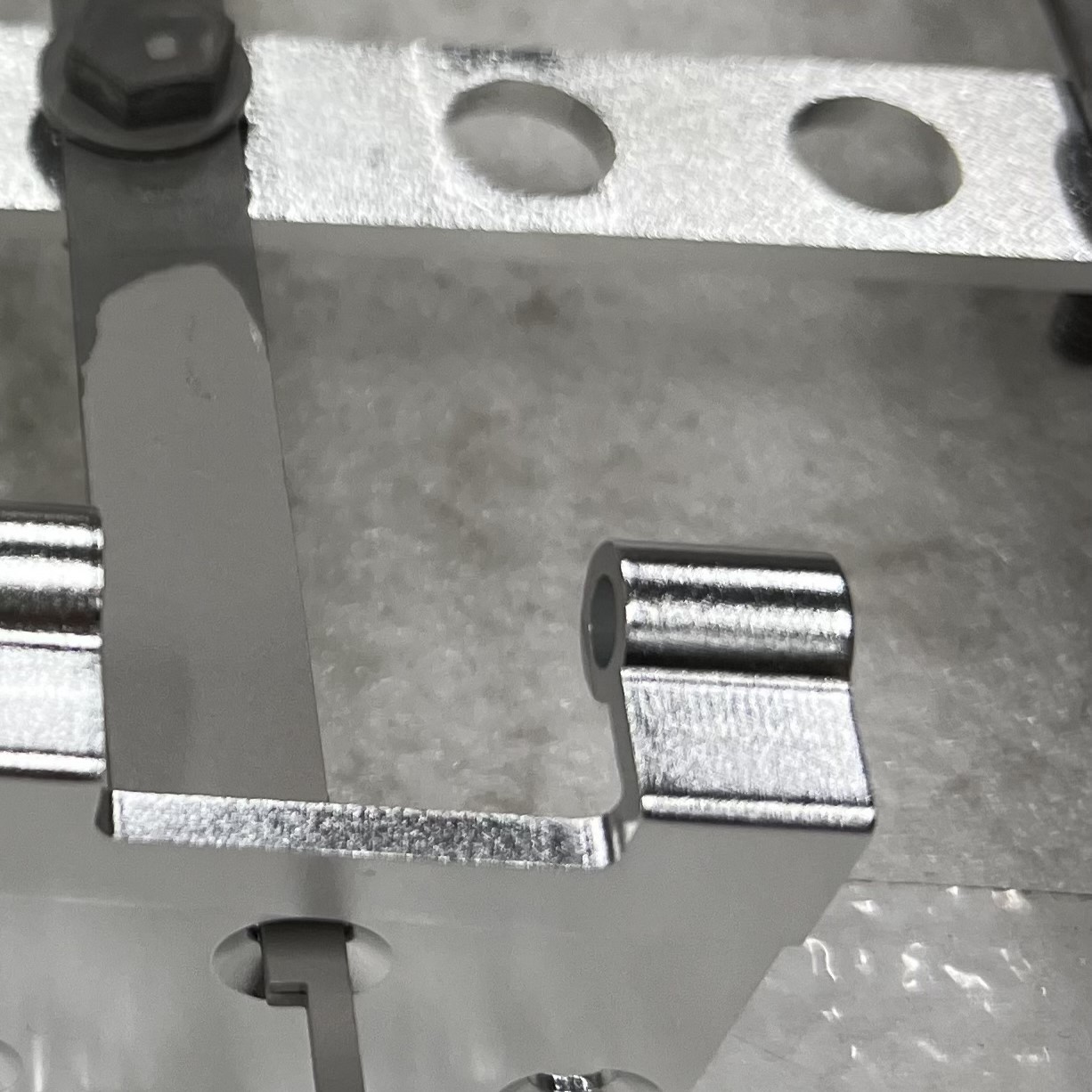

- Our skilled technicians can handle intricate part geometries. Whether it’s curved surfaces, intricate profiles, or irregular shapes, Bright Dip Anodizing delivers consistent results.

Recreational & Sporting Goods:

- Yes, even your favorite flashlight, baseball bat, or paintball gun can benefit from Bright Dip Anodizing. Not only does it enhance their appearance, but it also adds durability.

Suitable Aluminum Alloys for Bright Dipping:

The degree of brightness achieved depends on the type of aluminum alloy and the part’s surface finish. Here are some alloys most suitable for bright dipping:

- 1XXX

- 5XXX

- 6XXX

- 7XXX

Technical Details for Bright Dipping:

Thickness:

- Ranging from 0.0001 to 0.0007 inches (100-700 microinches).

What Is Bright Dip Anodizing?

Bright Dip Anodizing is a specialized metal finishing technique designed to enhance the aesthetic appeal and longevity of aluminum components. Here’s how it works:

Step 1: Bright Dipping:

- This initial step involves immersing aluminum parts in a chemical bath known as the bright dip solution. The solution typically contains a combination of phosphoric and nitric acids, along with other additives. These acids work their magic by smoothing out microscopic irregularities on the surface, resulting in a glossy, high-luster appearance.

Step 2: Anodizing:

- After bright dipping, the aluminum parts undergo anodizing. In this process, the components are immersed in an acid electrolyte bath with a cathode. By passing an electrical current through the bath, a protective oxide layer forms on the surface of the treated aluminum. This oxide layer not only enhances the visual appeal but also provides crucial protection against scratching, fading, and corrosion.